(Photo: ZEISS)

(Photo: ZEISS)

(Photo: ZEISS)

A reader left a message for “The Battle of the Lithographic Machines” stating that Germany’s Zeiss is the true king, questioning why I don’t make lithographic machines myself.

This is actually not a stupid question. If Nikon and Canon can collaborate with Zeiss, why can’t Zeiss do it themselves? In fact, Zeiss has actually made lithography machines before.

In the book “ASML’s Architects” (tentatively named “The Legend of ASML”) that I translated, there is a detailed account of Zeiss’s story. There are many unknown stories in the middle, which inspired me to share some of the details today.

Chapter One Link to heading

Carl Zeiss AG has a history of over 170 years, with many ups and downs along the way, but let’s begin with the Second World War.

During World War II, Carl Zeiss was the main supplier of telescopes, rangefinders, and various sighting devices for the German military’s artillery and fighter planes. Its well-known T coating prevented sniper scopes from being exposed by sunlight reflections, greatly enhancing combat effectiveness.

Because Germany’s optical technology was superior to that of the United States at the time, in April 1945, General Patton led the Third Army into the Soviet-occupied area of East Germany, disregarding the risk of violating the Yalta Agreement, and occupied Jena and Dresden where Zeiss was located.

The Americans were planning to move the entire Carl Zeiss company to West Germany using 600 trucks, but the rapid advance of the Soviet army in Germany ruined their plan. In the end, the Americans could only take 84 core technical and management personnel from Carl Zeiss and 41 from Schott, and established a new Carl Zeiss headquarters in Oberkochen, West Germany. This is the headquarters of Carl Zeiss today.

The Soviet Union then heavily abducted the remaining experts and equipment of the Carl Zeiss factory. It is remarkable that the craftsmen who had been grinding glass for generations in Jena themselves quickly rebuilt the East German Carl Zeiss.

At the time of the reunification of Germany in 1990, Carl Zeiss in West Germany had 15,000 employees, while Carl Zeiss in East Germany had 50,000 employees.

Due to politicians’ intervention, the West German company Zeiss reluctantly merged with the struggling state-owned company Zeiss in East Germany. At that time, Zeiss had already been beaten back by Japan and its own Contax and Pentax camera brands had been sold to the Japanese. Zeiss’s proud mechanical shutter had no defense against electronic measurement and electronic shutter technologies from Japan.

The Swedish Hasselblad that had previously collaborated with Zeiss on a lunar mission began to shift towards Japanese technology, which was a heavy psychological blow at the time.

Chapter Two Link to heading

At this time, ASML, which had been losing money for 5 years, was preparing to take off. At the same time, Zeiss, which was also short of money and was laying off employees, became a “stumbling block”. Selling a few dozen sets of lithography machine lenses per year was not a big business for Zeiss, but it was a lifeline for ASML. In 1990, only 10 sets of i-line lithography lenses could be grinded out by Zeiss’s six top craftsmen.

After rough grinding the machine, the laser measurement draws a surface relief map of the lens. Then, the craftsmen at Zeiss, who are called “golden fingers,” rely entirely on their sense of touch to carefully polish off parts that differ in height by a few dozen nanometers while watching the map, in order to achieve a sense of symmetry.

Due to a shortage of personnel, Zeiss has traveled around the world in search of such skilled craftsmen, but still cannot find the necessary forty people.

Even worse, there are constant issues even with the produced shots.

The craftsmen diligently polished the lenses to perfection, yet distortion was still present in the projected patterns during IBM lithography experiments. Despite months of precise measurements, the curvature of the lens itself and any design issues could not be identified.

Finally, the conclusion is that the tiny stress present in the lens glass may be the fundamental cause of image distortion. However, another century-old glass expert under the Carl Zeiss group, Schott, states that it is difficult to reduce stress to the delicate degree required by lithography machines.

More problems have emerged in chip factories. Micron has found that after a period of time, the light transmittance of Zeiss lenses will significantly decrease. After careful analysis, it was discovered that extremely tiny carbon deposits had accumulated on the surface of the lenses.

This enigmatic problem is something that nobody could have predicted.

The lens group of Zeiss is sealed with low-pressure helium because the difference in refractive index between this inert gas and vacuum is six times lower than that of air. It was later discovered that the adhesive used in lens bonding contains carbon and reacted under the catalytic action of high-energy ultraviolet light in the lithography machine.

Chapter Four Link to heading

The specific solutions to these problems are not the focus of this article for discussion.

After its establishment, ASML went through a series of difficulties and various issues. It almost didn’t make any profit for the first ten years. In particular, Del Prado, the visionary founder of ASM, personally facilitated the company’s establishment. However, even without making any significant mistakes, he had to step down with a loss of $35 million.

This is just the torrent of the big times, and it is getting increasingly difficult for a single individual or company to undertake large-scale R&D projects.

Today, the development of a single 7nm chip requires an investment of up to 300 million US dollars. Even companies with abundant financial resources like Huawei still rely on support from companies such as ARM, TSMC, and Cadence. TSMC, which invests over 10 billion dollars annually, also depends on various semiconductor equipment and raw material manufacturers.

So, in the face of our country’s current situation, I want to digress a bit and take a look at how the United States rose to power.

Chapter Five Link to heading

From the American Civil War in the 1860s to 1900, there were 40 years of expansion in American universities. The total number of universities increased tenfold from 600 to 6000, and the engineering boom also contributed to the rapid development of American industry.

Now, several major engineering schools in the Top 10 (Stanford, MIT, Caltech, Berkeley, and Caltech) were born during this period. It is important to note that at this time, America had already been established for a hundred years, making these schools relatively new. The prestigious, long-established schools such as Harvard, Yale, and Princeton were established even earlier.

Later on, many giant companies of the past century, such as General Electric, Coca-Cola, and American Express, were also founded during that period.

The construction of the subways in Chicago, Boston and New York, which started around 1900, also represented symbols of the manufacturing industry leadership, just like high-speed railways do today.

Around 1900, the United States caught up with the British Empire and became the world’s top economy in terms of GDP.

Do you feel a sense of familiarity? It has been 40 years since the implementation of China’s reform and opening-up policy, and engineers have been reaping the benefits for many years.

Chapter Sixth Link to heading

Although the GDP surpassed that of the British Empire, what was the true strength of the United States at the time? And why did it take them a full three to four decades to truly establish their dominant position? Let’s examine this from a technological standpoint, setting aside other factors.

Quantifying technology can be quite challenging, so we often use fundamental science as a substitute. Fortunately, the Nobel Prize has been in place since 1901, and its authoritative status is indisputable.

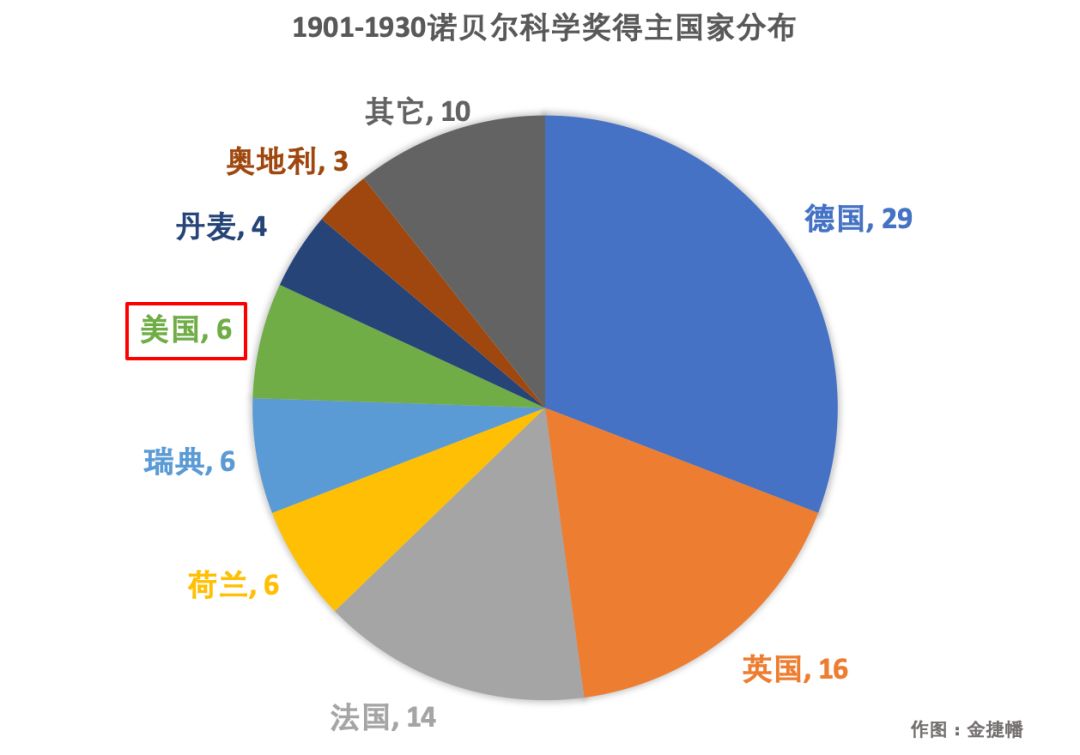

Let’s take a look at how the scientific level of the United States has evolved in the 30 years since it became the world’s largest economy in terms of total GDP.

This graph excludes the literature and peace awards. As we can see, the United States was far behind Europe in scientific research during the early 20th century, and even incomparable to Germany, England, and France individually. I specifically checked and found out that among the six American winners, three of them were actually European immigrants.

At that time, Germany’s strong scientific and technological capabilities can also explain why they had the confidence to launch two world wars. Germany’s Bismarck battleship, V2 missiles, night fighters, Tiger tanks, etc. were all exceptional. However, with a population of only seventy million and a lack of oil, Germany clearly could not simultaneously engage in military confrontation with the United Kingdom, the United States, and the Soviet Union.

Of course, there is a certain lag in the awarding of the Nobel Prize. However, the delay in those days was not as much as it is today, so it is still sufficient to explain the issue.

At that time, the scientific centers were Munich, Gottingen, Copenhagen, or Cambridge, but definitely not Harvard or Stanford.

Since the 1930s, the wave of anti-Semitic sentiment in Europe led by Nazi Germany has grown increasingly intense. A large number of Jewish scientists immigrated to the United States, and many other scientists of various ethnicities also came to the United States to escape the turmoil of war.

Many European Nobel Prize winners, such as Einstein, Frank, and Fermi, emigrated to the United States, which can be seen as a sign of the shift of the world’s scientific center from Europe to the United States. After Germany’s surrender in 1945, the United States immediately sent 3,000 scientists in military uniform to Germany to collect technological information and take scientists with them. The previously mentioned company Carl Zeiss was just one of them.

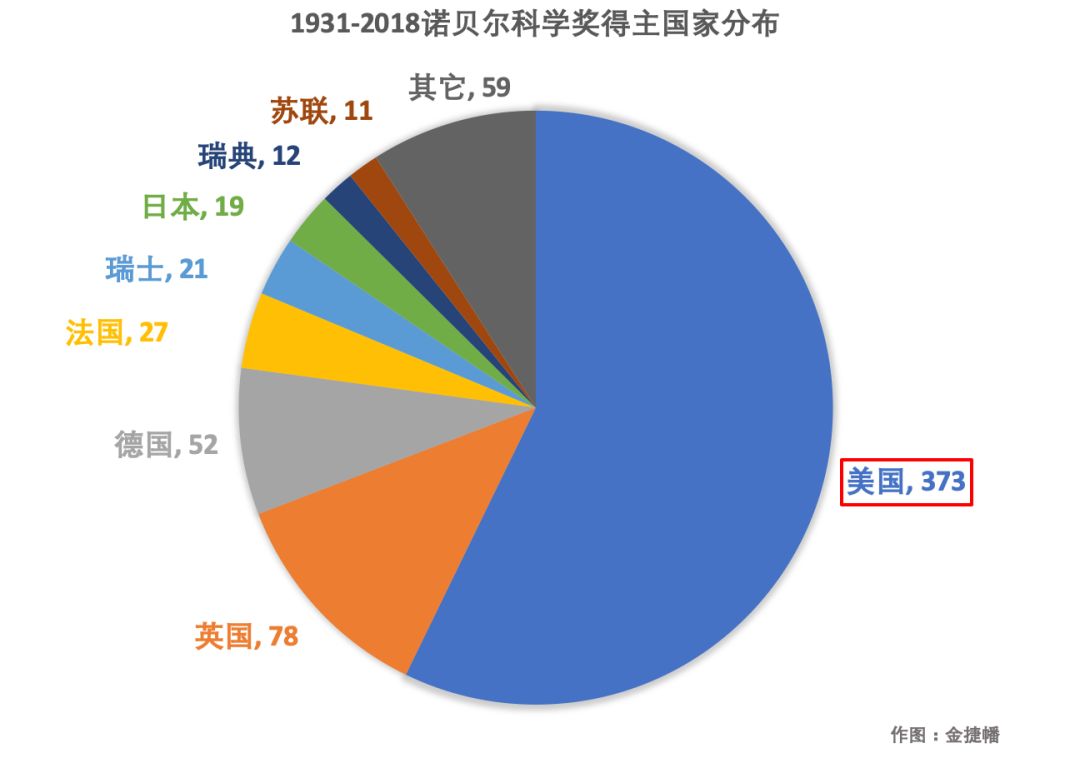

Let’s take a look again at the distribution of Nobel Prizes in the latter half of the 20th century, distinguishing them based on the location of the laureate’s workplace.

As can be seen from the above figure, the United States has established an overwhelming advantage in basic scientific research. This has enabled the United States to take the lead in high-tech basic research such as electronics, materials, and biology, and to have a great advantage in specific application fields such as aerospace, medicine, chemistry, and semiconductors.

Chapter Seven Link to heading

Japan, South Korea, and Europe have found their own niche in delving deeper into the manufacturing industry. Challenging the dominance of the United States is not their goal.

The greatest benefit of the information age is that the world has become flatter. Today’s open source trend and various IP authorizations make it possible for our country to take a shortcut in the IT field. Various top basic scientific research results around the world can also be downloaded with just a few clicks of the mouse.

Talent is the only problem that needs to be solved, and it seems that the opportunity for discrimination against Jewish people, as seen in the United States in the past, could arise again. Foreign graduates from American universities now find it very difficult to stay in the United States, and the H1B lottery system is a concern for many students. Therefore, China’s more proactive immigration policy is definitely more advantageous than disadvantageous.

Sorry, I’ve gone too far off topic today and it’s hard to bring it back.

Chapter Eight Link to heading

Carl Zeiss in East Germany did indeed produce photolithography machines for the Hua-Yue Alliance at that time, but the quantity was not substantial. ASML once sent three people to investigate and found that in Jena, there was only a hotel with twenty rooms, and the entire valley was shrouded in smoke from coal burning.

Various backwardnesses compromised the competitiveness of Zeiss’s lithography machines, but its optical expertise is beyond doubt. By delving deeply into the potential of its engineers in the high-tech field, Zeiss has re-established its leading position in the industrial and medical optics sectors.

Today, in Zeiss’ four major business groups, the Semiconductor Manufacturing Technology Business Group (SMT) has been ranked first, contributing one-quarter of the company’s revenue. ASML has acquired a quarter of the shares in SMT.

Carl Zeiss is assembling the optics module for ASML EUV in a clean room (Photo: ZEISS).

ASML and Zeiss have completely different corporate cultures: ASML is aggressive and forward-looking, while Zeiss is conservative and tolerant. According to Rene, the author of “ASML’s Architects,” the differences between the two companies are as far apart as the first and last letters of the alphabet, and the number of conflicts between them is countless.

But those years when top engineers were burning with passion together still make people envy endlessly.